The most significant difference between the COVID-19 pandemic and previous pandemics is the multiplier effect of transportation and communication speed in a pandemic spread. When considering the place and contribution of other beings in nature, the process has resulted in a deterioration of the ecological balance.

INTRODUCTION

You make a design, promote it and print only the items you sell. The best part is that the POD company with which you work, will print your shirt out of stock and send it to your customer directly. This simple procedure organisation allows you to start a new type of business in which you can earn money by selling a variety of your designs, not just your t-shirts, you can sell a wide range of POD items, apparel (t-shirts, skirts, leggings, hoodies and sweaters), tapestries, storage boxes, placemats, tablecloths, lunch bags, towels, accessories cases.

Print-on-demand companies provide catalogues of blank products that are just waiting for your designs. Because you don’t need to buy stock and ship yourself you don’t need a storage facility, furthermore, because the print-on-demand strategy eliminates the initial costs of selling your branded items, you have more time and resources to build a following for your products. It’s the quickest way to start building your own lifestyle business.

THE BIRTH OF PRINT-ON-DEMAND

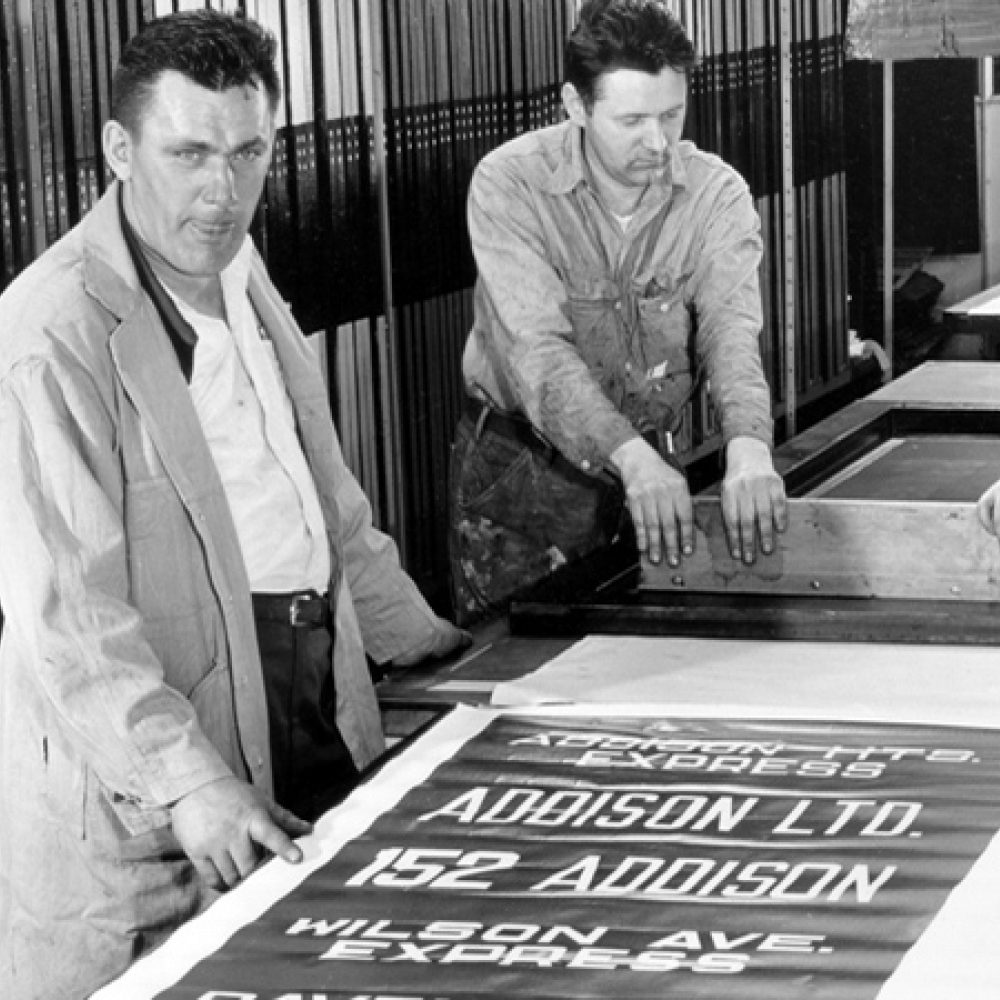

This process and the start of the industry came into being in the sixties, during this period, the artist and inventor Michael Vasilantone presented a new screenprint option that made the creation of unique designs easier. Then printers were made available to the public during the 1980s. At this point, on-demand printing began to thrive. It only included printing on paper at first, but with direct printing, it quickly changed. The first example was in the 1990s when several brands started providing this particular service.

Personalisation is one of the most popular trends in the print-on-demand industry today. Customers want one-of-a-kind products such as t-shirts and a variety of other clothing items. In the print-on-demand industry, a variety of different processes are now used.

Digital printing is one of the most popular options, this method employs inkjet printers that print directly on the textile. Roller printing, on the other hand, is based on technology that dates back to the 18th century. Designs are stamped on the fabric in this case. Finally, there is screen printing. In this method, mesh and stencils are used to push the ink onto the fabric. The option you select will be determined by the result you are attempting to achieve, for example, digital printing is an excellent choice for ensuring that even the smallest details are perfect, it’s also useful if a design incorporates a variety of different colours. Screen printing, on the other hand, is a good option when colours need to be extremely vibrant for a specific design. It can also be used because it is more cost-effective and faster than digital printing. As a result, it is frequently used for bulk printing of products.

THE SUSTAINABILITY OF PRINT-ON-DEMAND

We do not doubt that the current global crisis has affected all of us, but if there is one larger battle looming, it is unquestionably the global climate-environmental crisis. As pioneers within the print-on-demand industry, we take this ongoing issue very seriously, which means that we recognise the beauty of the business model in its sustainability but always strive to find new ways to make the model even more environmentally friendly.

Each product is printed to order with the print-on-demand business model, so there is no wasted stock or excess materials. Furthermore, the significant amounts of water pollution, wasted energy, and dye that was typically produced in traditional printing methods are no longer present in products that are meticulously produced with care. The business model is also extremely efficient, with products going from idea to print, to shop floor or eCommerce store in days, as opposed to weeks or months before the model’s popularity. The number of (air) miles traveled by the garment will be drastically reduced, making the business model a sustainable investment.

Today’s digital print industry provides a clean future for the environment, and as consumers and buyers become more aware of their environmental choices and the true impact those choices have, digital technologies and their application will continue to advance to replace unsustainable inefficient manufacturing. Manufacturing’s hidden waste is now being addressed and harnessed through innovative recycling processes, whether it’s energy, water, textile fibers, inks, or the fabrics we wear, and this sector is expanding to meet the demands of the environmentally-conscious consumer.

SO, WHAT’S NEXT?

We are constantly refining our strategy and business model to ensure that it meets, if not exceeds, government standards. We are not only personalisation pioneers, but also a community concerned with environmental protection, and as the print-on-demand revolution takes hold, we hope you will join us on this sustainable and exciting journey into the future of printing.

TRUSTED BY 1000’s OF CUSTOMERS

Behind the scenes we persistently work on your growth; developing your ideas into a realistic production flow, we require no customer-facing credit as our growth is partnered with yours.

OUR TEAM

LOVE TO HELP

GROW YOUR

BUSINESS

QUICK CONTACT

You can contact us on sales@cwondemand.com alternatively you can complete the below form and we will respond as soon as possible.